In a globalized world where goods are produced and traded across borders, it becomes increasingly important to understand how American manufacturing standards stack up against those in other countries. The success and competitiveness of a country’s manufacturing industry greatly depends on the quality and consistency of its products. In this article, we will explore the various factors that contribute to American manufacturing standards and examine how they compare to those found in other nations. By gaining insight into these standards, we can better appreciate the strengths and areas for improvement within the American manufacturing landscape.

American Manufacturing Standards

History and Evolution of American Manufacturing Standards

American manufacturing standards have a rich history that dates back to the Industrial Revolution in the late 18th and early 19th centuries. During this time, the United States emerged as a global leader in industrialization and manufacturing, spurred by advancements in technology and the availability of natural resources. As American industries began to flourish, the need for standardized manufacturing processes became increasingly evident.

The development of American manufacturing standards can be attributed to the efforts of industry leaders, policymakers, and organizations such as the American Society for Testing and Materials (ASTM) and the National Institute of Standards and Technology (NIST). These entities played a crucial role in documenting and establishing guidelines for various industries, ranging from automotive and electronics to pharmaceuticals.

Over the years, American manufacturing standards have evolved to meet the changing needs of industries and consumers. Advancements in technology, globalization, and increased competition have influenced the development of more stringent standards with a focus on efficiency, safety, and quality.

Key Factors Influencing American Manufacturing Standards

Several factors have significantly influenced the development of American manufacturing standards. One key factor is the commitment to innovation and technological advancement. American industries have prioritized research and development, leading to the adoption of cutting-edge manufacturing technologies and processes.

Moreover, the emphasis on consumer safety and product quality has played a pivotal role in shaping American manufacturing standards. The United States has a robust regulatory framework in place to ensure the safety and quality of manufactured goods. Agencies such as the Food and Drug Administration (FDA) and the Consumer Product Safety Commission (CPSC) enforce regulations to protect consumers and promote fair trade practices.

Additionally, the evolving global marketplace and the need for competitiveness have driven American manufacturing standards. With the rise of international trade, American manufacturers have been compelled to meet global standards in order to remain competitive and expand into foreign markets.

Impact of Regulations on American Manufacturing Standards

Regulations play a crucial role in shaping American manufacturing standards by establishing guidelines and requirements for various industries. These regulations cover a wide range of areas, including safety, environmental protection, labor practices, and product labeling.

While regulations can sometimes be seen as burdensome by manufacturers, they also serve to uphold the reputation of American-made goods. By ensuring compliance with rigorous standards, regulations instill confidence in consumers and foster trust in the marketplace.

Regulations also aim to level the playing field by setting minimum standards that all manufacturers must meet. This ensures fair competition and prevents the exploitation of labor or the production of unsafe products.

Quality Control and Assurance in American Manufacturing

One of the key pillars of American manufacturing standards is quality control and assurance. American manufacturers understand the importance of producing goods that meet or exceed consumer expectations.

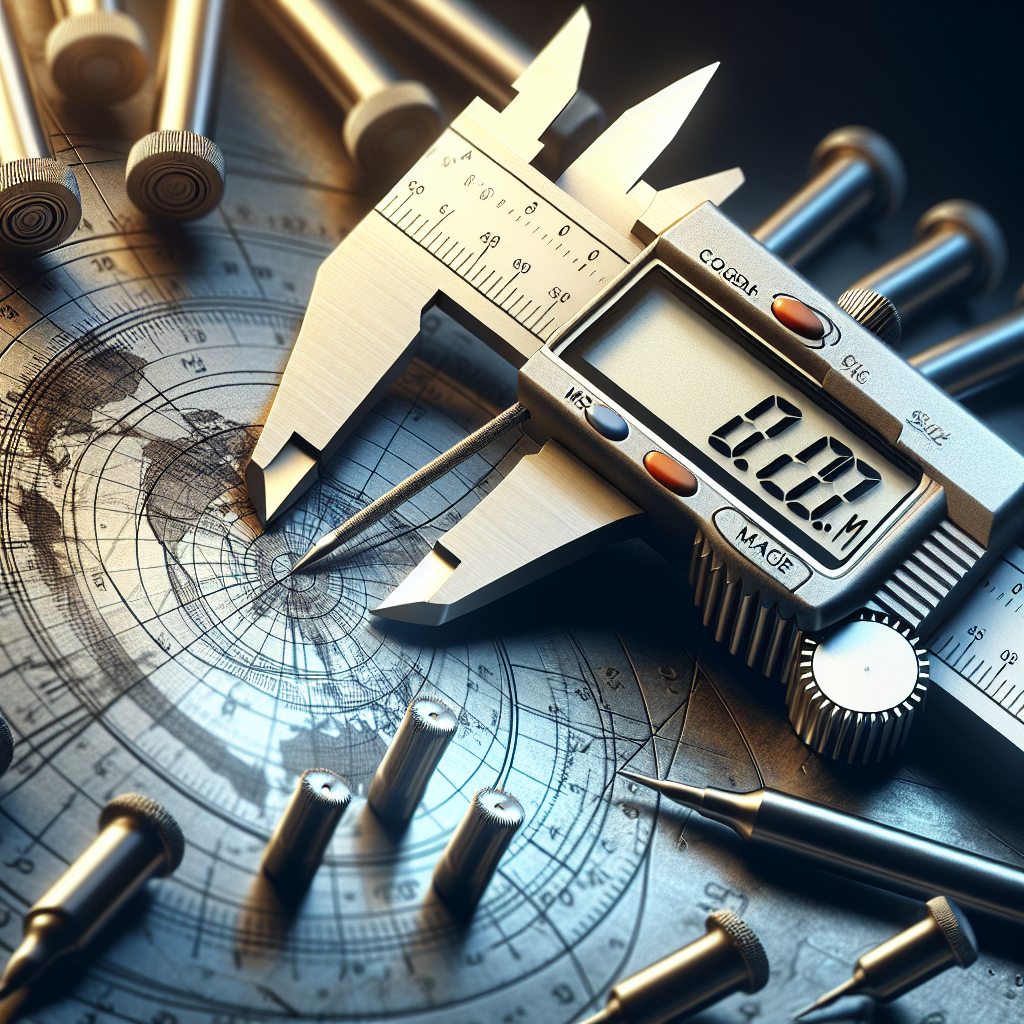

Quality control measures involve the implementation of rigorous inspection processes at every stage of production. This includes testing raw materials, monitoring production processes, and conducting final product inspections.

To aid in quality control, American manufacturers often adhere to industry-specific standards developed by organizations like ASTM and NIST. These standards outline specific requirements and procedures for manufacturing processes and test methods, ensuring consistent quality across the industry.

Moreover, American manufacturers have also embraced automation and advanced technologies such as artificial intelligence and machine learning to enhance quality control and minimize production errors. These technologies help detect defects and deviations from standards, leading to improved overall quality.

Competitiveness of American Manufacturing Standards

American manufacturing standards have positioned the country as a global leader in various industries. The rigorous standards followed by American manufacturers have earned them a reputation for producing high-quality, reliable, and safe products.

Furthermore, the adherence to strict manufacturing guidelines has allowed American manufacturers to remain competitive in the global marketplace. By meeting and exceeding international standards, American-made goods often enjoy a competitive advantage.

Additionally, American manufacturing standards are continuously evolving, driven by innovation and the changing needs of industries. This adaptability ensures that American manufacturers can stay ahead of the curve and meet the demands of an ever-changing global market.

International Manufacturing Standards

Popular International Manufacturing Standards

Internationally, several manufacturing standards have gained widespread recognition and adoption across various industries. These standards aim to harmonize practices and ensure consistency in manufacturing processes worldwide.

The International Organization for Standardization (ISO) is one of the main bodies responsible for developing international manufacturing standards. ISO standards cover a broad range of areas, including quality management, environmental management, and occupational health and safety.

ISO 9001 is perhaps the most well-known and widely adopted ISO standard. It outlines requirements for a quality management system and provides guidance on achieving customer satisfaction and continuous improvement.

ISO 14001 focuses on environmental management, helping organizations establish and maintain environmentally friendly practices. This standard encourages sustainable manufacturing processes and the reduction of waste and emissions.

ISO 45001 is the international standard for occupational health and safety management. It helps organizations identify and address potential risks to ensure a safe and healthy work environment.

Comparison of International Manufacturing Standards with American Standards

American manufacturing standards, while robust, are not always identical to international standards. There are similarities and differences between American and international manufacturing standards, reflecting the unique needs and priorities of each region.

In some cases, American manufacturing standards may align closely with international standards, especially when it comes to quality control, safety, and environmental protection. This consistency allows for smoother integration and collaboration between American and international manufacturers.

However, variations in regulations, cultural practices, and market demands can result in differences between American and international manufacturing standards. These differences may affect manufacturing processes, product specifications, and testing requirements.

Nevertheless, efforts are being made to harmonize manufacturing standards globally. Organizations like ISO work towards aligning standards across nations and facilitating international trade. Harmonization allows manufacturers to streamline processes, reduce compliance costs, and broaden their global reach.

Challenges and Opportunities

Challenges Faced by American Manufacturing Standards

While American manufacturing standards have achieved significant success, they are not without challenges. One crucial challenge is the rapid pace of technological advancement. As technology evolves, manufacturers must adapt their processes and standards to remain competitive and meet evolving consumer demands.

Ensuring regulatory compliance is another challenge faced by American manufacturers. Regulatory landscapes can be complex and vary across different sectors and jurisdictions. Manufacturers must navigate through these regulations to maintain product quality and safety while remaining compliant.

Additionally, global competition presents a challenge to American manufacturing standards. As emerging economies develop their manufacturing capabilities and adhere to international standards, American manufacturers face increased competition. To maintain their competitive edge, American manufacturers must continue to innovate and improve their standards.

Opportunities for Improvement and Collaboration on Manufacturing Standards

Despite the challenges, there are numerous opportunities for improvement and collaboration on manufacturing standards. Collaboration between industry leaders, policymakers, and standardization bodies can lead to the development of more inclusive and globally recognized standards.

Investing in research and development is vital to drive innovation and enhance manufacturing standards. By leveraging emerging technologies and embracing automation, American manufacturers can improve efficiency, reduce costs, and enhance product quality.

Furthermore, opportunities for international partnerships and collaborations can help American manufacturers expand their reach and tap into new markets. By working together with international manufacturers, American companies can learn from best practices and adopt innovative manufacturing techniques.

Public-private partnerships can also play a significant role in enhancing manufacturing standards. By fostering collaboration between government agencies, industry associations, and manufacturers, these partnerships can lead to the development of practical guidelines and regulations that balance safety, quality, and competitiveness.

Case Studies

Case Study 1: Automotive Industry

The automotive industry serves as an excellent case study to understand the impact of manufacturing standards. American manufacturers in the automotive industry have adopted strict quality control measures and implemented standardized manufacturing processes.

These standards have not only ensured the safety and reliability of American-made vehicles but have also strengthened the industry’s competitiveness. American automobile manufacturers are known for producing vehicles that meet rigorous safety and quality requirements, resulting in consumer confidence and increased market share.

Case Study 2: Electronics Industry

The electronics industry is another sector where manufacturing standards play a crucial role. American manufacturers in this industry adhere to various standards to ensure the quality, reliability, and safety of electronic products.

Strict adherence to manufacturing standards allows American electronics manufacturers to offer products that meet international requirements. This enables them to export their products to global markets and compete against manufacturers from other nations.

Case Study 3: Pharmaceutical Industry

The pharmaceutical industry is highly regulated and governed by stringent manufacturing standards worldwide. American pharmaceutical manufacturers follow Good Manufacturing Practices (GMP) guidelines established by regulatory bodies like the FDA.

These standards ensure that pharmaceutical products are manufactured and controlled in a consistent manner, guaranteeing product quality and patient safety. Adherence to these standards has allowed American pharmaceutical manufacturers to maintain their reputation for producing safe and effective medications.

Implications for Global Trade

Effects of Different Manufacturing Standards on Global Trade

Differences in manufacturing standards can have significant implications for global trade. Varying standards can create barriers to entry for manufacturers looking to enter foreign markets. This is particularly true for industries with stringent regulations, such as pharmaceuticals and automotive.

Misalignment between manufacturing standards can also lead to inefficiencies and higher costs. Manufacturers may need to modify their products or production processes to meet the requirements of different markets, increasing the complexity and cost of doing business internationally.

Additionally, differing standards can impact consumer perception and trust. Consumers may have varying expectations regarding quality and safety, resulting in a preference for products that align with their own country’s standards. This can influence purchasing decisions and create challenges for manufacturers looking to expand globally.

Importance of Harmonization and Standardization in International Trade

Harmonization and standardization of manufacturing standards are vital for facilitating international trade. Aligning standards across countries allows for a smoother exchange of goods and services, reducing trade barriers and increasing market access.

Standardization also improves interoperability and compatibility of products across different markets. When products meet consistent standards, they can be integrated seamlessly into global supply chains and cater to a wider customer base.

Moreover, harmonization and standardization promote fair competition among manufacturers. When all manufacturers adhere to the same set of standards, it ensures a level playing field and prevents the creation of unfair advantages.

In summary, American manufacturing standards have a strong foundation and have evolved over time to meet the changing needs of industries and consumers. The commitment to innovation, consumer safety, and competitiveness has driven the development of robust standards in the United States. While variations exist between American and international manufacturing standards, efforts to harmonize standards globally are underway. Challenges present opportunities for improvement, collaboration, and innovation. By embracing these opportunities and striving for harmonization, American manufacturers can continue to thrive in the global marketplace while ensuring quality, safety, and competitiveness in their products.